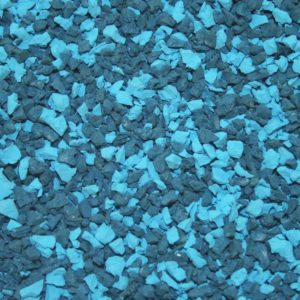

When playground administrators have chosen to install loose-fill material, they often find themselves comparing either rubber mulch (also called shredded rubber mulch, tire mulch, rubber nuggets, rubber pellets, recycled rubber mulch, rubber chips, or loose fill rubber), wood chips (such as landscape mulch), or engineered wood fiber mulch (EWF). All of those are considered loose-fill materials. On the other hand, unitary playground surfaces are all connected (ex. poured-in-place (PIP) playground flooring, rubber playground tiles, bonded rubber mulch).

Rubber Mulch is Popular, But is it the Best Option for Playground Flooring?

Today’s playgrounds look much different than they did even a decade ago. The drive to make playgrounds safer and accessible to children with special needs has led to significant developments in the technology used to manufacture the materials that go into making playgrounds. Playground flooring, in particular, has undergone significant improvements. If they’re not already, playgrounds with asphalt or concrete surfacing will become extinct because they simply don’t make sense anymore. There are plenty of newer, safer, and cost-effective materials to choose from.

So, is rubber mulch a good option for playground surfacing? It’s certainly popular. But we all know that “popular” doesn’t always mean “best”. Let’s examine the pros and cons of using rubber mulch for playground flooring. Whether you’re installing a brand new playground or resurfacing an existing one, you’re probably wondering about these four topics:

Safety of Rubber Mulch Playground Flooring

One of the basic and most important considerations in playground safety is how its surfacing impacts its critical fall height requirements, which have to do with shock absorbency. The regulations surrounding fall height take into account the vertical distance between the highest-designated play surface on a piece of equipment, and the playground surface beneath it (see this PDF: Public Playground Safety Handbook from the Consumer Product Safety Commission for more details). These requirements come from American Standard Testing Methods (ASTM), the institution tasked by the federal government with setting industry safety standards.

Pros:

- If using the right type of rubber mulch and installed in a proper manner, rubber mulch can be able to provide an adequate degree of protection to children, meeting acceptable ASTM standards. From the Consumer Product Safety Commission: “There are also rubber mulch products that are designed specifically for use as playground surfacing. Make sure they have been tested to and comply with ASTM F1292.” (source)

- Experts agree that rubber materials make for the safest playground surfaces.

- In addition, most manufacturers of rubber mulch utilize safe materials that are mostly free of wire, fiber, plastic, wood, and other undesirable contaminants.

Cons:

- It’s easy for litter, debris, and foreign objects to become buried in the mulch, posing a potential safety hazard. The CPSC warns that “Recycled tire rubber mulch products should be inspected before installation to ensure that all metal has been removed.”

- When in direct sunlight, the surface can get hot.

- Ask anyone using a wheelchair, walker, scooter, etc and they’ll tell you it’s tough (if not impossible) to get around on tire mulch. So if you’re looking for an accessible playground flooring option that doesn’t cause mobility issues for those with disabilities, you should probably consider something like rubber tiles or poured rubber.

- You’ll also need to spend time keeping an eye out for insects building homes in the mulch.

Cost of Rubber Mulch as a Playground Surface

Pros:

- Rubber mulch is in the lower-middle price range of playground surfacing. Installation of rubber mulch playground surfacing varies per square foot, based on factors such as how large the playground is, if you’re outsourcing the installation, product availability in your area, and where you’re buying it from. Your best bet is to shop around online and decide whether you’ll install it yourself or pay someone else to install it. You can expect rubber mulch to have a slightly higher up-front cost than wood mulch, because of the better quality of its materials.

Cons:

- Amount of surfacing needed. Because of fall-height requirements, rubber mulch requires 6 inches of material to protect a child from a 10-foot fall. Compare that to a poured rubber surface, which only needs 4.5 inches of material to allow a child to safely land from a 10-foot fall.

- After the initial installment, loose fill materials like shredded rubber, are on the more expensive end of maintenance requirements. Rubber tire playground mulch must be replenished regularly due to the nature of the material. Over time, this type of material is prone to being washed away during storms, and kicked out of the playground by busy feet and other types of activity.

Quality of Rubber Mulch Playground Flooring

Pros:

- You can expect rubber mulch to last about 10 years before needing to do a comprehensive replacement of the material. (That being said, you’ll have to top off the rubber playground mulch during that time, which can add up.)

- It’s not biodegradable and does not decompose like natural wood.

Cons:

- It’s dusty. There’s no way around this. If you or your kids have played on a playground with shredded/recycled tire surfacing, you know how gross you feel after using it.

- With a loose fill material like shredded/recycled rubber mulch that can wash away, you may find you need to replace or replenish it sooner than what is recommended. That’s particularly the case if the playground is located in an area that does not allow for adequate rainwater drainage.

Installation of Rubber Mulch Playground Flooring

Pros:

- Loose fill materials are generally easily transported and installed, and the same is the case for tire mulch. While we recommend installation by a professional in any scenario, those on a strict budget may be able to research installation instructions to be able to complete it themselves. You can buy rubber mulch at various places online, as well as at some hardware or lawn/garden stores.

Cons:

- As mentioned above, the depth of the material needs to be carefully monitored and immediately replenished when it falls under the accepted safety level.

- You can’t be as creative with designs as you can with other surfacing types, such as poured-in-place rubber, which allows for playground games to be built directly into the surface.

Next Steps

There are pros and cons to every playground surface type. You’ll want to also consider factors such as climate in your area, budget, product availability, and location constraints.

Loose-fill rubber playground mulch (which we don’t install) isn’t the only rubber playground surfacing option. For larger playgrounds (at schools, parks, daycare centers, and other public playgrounds), we recommend considering a uniform rubber surface like poured-in-place rubber or rubber playground tiles. The reason we only install those options is because we honestly believe they’re some of the best surfacing options for your playground.

Again, we don’t install rubber tire chip playground surfacing (because we don’t think it’s the best option for kids or parents). You probably still have questions — contact adventureTURF for answers! We’d love to help you design the safest, most accessible playground surface possible! If you’re ready to take the next steps to choosing the right type of playground surfacing for your situation, reach out to us to request a free quote (for poured rubber or rubber tile playground surfacing). We’d love to help you create a place for adventure!

With so many different qualities and characteristics to consider, choosing a playground surface can be bewildering. That’s why we’ve created an ultimate guide of all the pros and cons of 11 of the most popular playground surfaces, from wood chips to recycled rubber mulch.

FAQ

Rubber mulch is in the lower-middle price range of playground surfacing. Installation of rubber mulch playground surfacing varies per square foot, based on factors such as how large the playground is if you’re outsourcing the installation, product availability in your area, and where you’re buying it from.

Depending on the installation, rubber mulch can provide an adequate degree of protection to children, meeting acceptable ASTM standards.

We recommend installation by a professional in any scenario, those on a strict budget may be able to research installation instructions to be able to complete it themselves. You can buy rubber mulch at various places online, as well as at some hardware or lawn/garden stores.

New playground surfacing isn’t inexpensive (

New playground surfacing isn’t inexpensive ( Not so long ago, playgrounds were fairly dangerous places for children to play. Monkey bars and climbing towers 10 feet tall, everything made of metal that gets hot in the sun not to mention its propensity to rust in the rain, and play surfaces that were made of rock hard dirt or even pavement. Safe playgrounds were not the norm. Children would often get severe burns from the metal play equipment and broken limbs or worse from falling off the tall contraptions onto hard surfaces. According to a study released by the

Not so long ago, playgrounds were fairly dangerous places for children to play. Monkey bars and climbing towers 10 feet tall, everything made of metal that gets hot in the sun not to mention its propensity to rust in the rain, and play surfaces that were made of rock hard dirt or even pavement. Safe playgrounds were not the norm. Children would often get severe burns from the metal play equipment and broken limbs or worse from falling off the tall contraptions onto hard surfaces. According to a study released by the