Rubber Surface Recapping & Restoration

Playground Surface Repairs

Not every playground requires a completely new poured-in-place rubber surface to be installed.

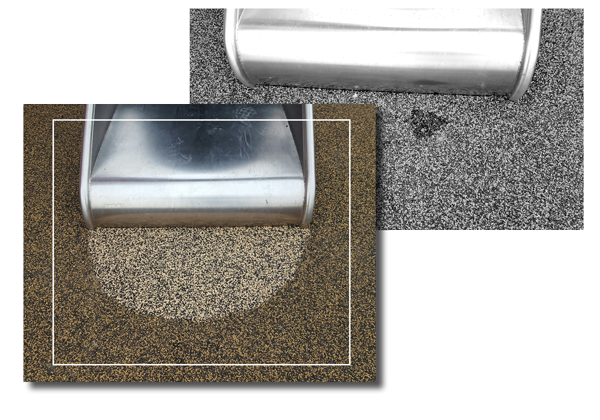

This restoration technique will actually improve the playground’s safety rating. It is also a budget saver, as the recap can provide the same brilliant color at less than half the price of a new poured-in-place rubber surface.Often a playground can be completely revitalized, by just adding a new color cap or wear layer to the surface.

Although poured-in-place rubber surfacing is very low maintenance, some simple upkeep is sometimes needed. We typically see some wear occur in high-traffic areas, such as under swings, at the base of slides, and around any merry-go-rounds or spinning equipment.

Small repairs are sometimes needed in these locations.

Playground Resurfacing Process

Though poured rubber playground surface is very durable, sometimes excessive use or other damage can occur. One of the nice things about the surface is it can be repaired. The process for the basic maintenance and repair of these poured in place surfaces is simple:

- First, we completely clean and remove any debris or loose pieces of the old poured-in-place rubber surfacing.

- Second, our staff will remove the existing cap on the rubber surface.

- Then we’ll mix the closest color match possible.

- Finally, we’ll patch in the new poured-in-place area, giving it a brand new look.

After a simple repair, the playground surface is as good as new!

Get a Quote

Have a poured rubber surface in need of repair or replacing?

Construction Companies & Contractors

See how we can work with you to install a poured playground or pool deck surface for your next job.

+Schools, Churches & Daycare Centers

Learn how we can work with you to install a safe surface on your playground.

+Playground & Landscape Designers

We can work with you to install a safety surface on the play area for your community project.

+HOA & Community Associations

We will install safety surfacing on your neighborhood playground or common area.

+Frequently Asked Questions

Rubber safety surface is a VERY durable product. It is 100% permeable and water drains right through it. Our customers are consistently amazed at the product’s ability to hold up in nearly any weather condition.

Both poured in place and rubber tile flooring can last as long as 12-15 years. If maintained properly, this lifespan is VERY attainable. The longevity it this flooring product is one of its biggest selling points. Please see our product warranty.

While the material is very durable under normal use, sometimes it can become damaged when new playground equipment is installed or the surface is exposed to unusual wear. There are a number of different solutions to improve or repair an old or damaged safety surfaces. We can tear out and replace the entire floor if necessary. However, there are many simple ways to improve the look or functionality of your existing surface. Learn more about the recapping and restoration process.

Performing maintenance on your poured rubber safety surface is as easy as regular cleaning or removal of rocks, spills and other debris. Simple tasks like the following will go a long way in ensuring your poured rubber safety surface lasts. Focus first on high traffic areas and use these best practices:

- Regular sweeping with a broom or leaf blower

- Low pressure water, soft soap, and some scrubbing

Click here to learn more

Poured in place surfacing can be installed in a variety of different ways to meet different budgets. The best way to save on the materials and installation cost is to use a 50/50 color/black mix. The colored rubber is still dominant in appearance. Believe it or not, the colored rubber is the most expensive portion of the cost of installation. We are happy to help our customers find ways to achieve the look they desire and save money in the process. Check out our playground installation project gallery, which includes mostly 50/50 black/color installs. This will give you an idea of what your project could look like utilizing a 50/50 color/black mix.