Picture the playgrounds you went to the most as a kid. They were covered in wood chip mulch, right? And you hated the splinters and sharp edges that it caused. Mulch (also known as “landscape mulch”) and wood chips have ruled the playground world for decades — but those responsible for playground upkeep (such as elementary school administrators, daycare directors, park maintenance crews, church managers, etc) have to deal with constant maintenance just to give the kiddos a place to play.

Wood Chips Are Popular, But Are They The Best Option for Playground Flooring?

Let’s take a closer look at using wood chips for playgrounds to see how they measure up to their competition in terms of safety, cost, and quality.

Safety of Wood Chips on Playground Surfaces

Pros:

- Wood chips have a degree of shock absorbency. A 9-inch layer of wood chips will allow a child to safely land from a 10-foot fall, according to American Standard Testing Methods (ASTM), the institution that sets industry safety standards such as this critical fall height requirement.

Cons:

- The Consumer Product Safety Commission (CPSC) says that CCA wood mulch is an “inappropriate surfacing” type for playgrounds. So make sure your wood mulch is not CCA-treated.

- They can obscure hazards, like broken glass from glass beverage containers.

- They can develop insect or mold problems.

- They can be choked on or swallowed by young children.

- While wood chips meet the requirements of the Americans with Disabilities Act (ADA) for playgrounds that require surfacing that lessens the impact of falls, they do not meet ADA requirements for surfaces that allow for wheelchairs and other mobility devices. So if you’re looking to build an accessible playground, wood chips aren’t your best option.

A further note on shock absorbency: One reason rubber playground surfacing has risen in popularity is because of the drastic difference in critical fall height requirements. Just 4.5 inches of poured-in-place rubber surfacing provides a surface on which a child can safely land from a 10-foot fall, compared to 9 inches for wood chips.

Cost of Wood Chips as Playground Flooring

Pros:

- Wood chips are one of the cheapest playground covering options, above only pea gravel and sand in terms of cost. You can generally expect to pay around $3 per square foot, installed.

Cons:

- Wood chips lose their color and texture over time.

- They require regular upkeep, such as raking for hazards and to maintain an even surface level. You will need to occasionally add new material to continue to meet safety standards and maintain the playground’s appearance, as the wood chips are gradually kicked out of the playground, lost in storm drainage, etc.

Quality of Wood Chips as Playground Surfacing

Pros:

- Those who choose wood chips as a playground covering often cite their visual appeal. Wood chips are a step up from traditional mulch, complement most landscaping, and are available in a range of colors.

Cons:

- One thing to watch out for in terms of color is whether or not the manufacturer uses dyes to enhance the color of the wood. Some of the dyes made for wood chips are known to cause reactions in people with certain medical conditions.

- Dust gets in eyes, on clothes, and causes a mess.

- Kids easily get splinters in it.

- Weeds can grow in it.

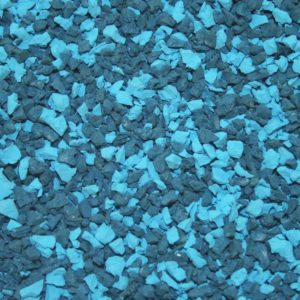

Those who choose poured-in-place rubber surfacing over options like wood chips often cite that they appreciate that we use only premium rubber made from natural materials: EPDM rubber (which helps the surface resist cracks due to severe temperatures and weather), and SBR rubber (which helps the surface stay flat and supple).

Installation of Wood Chips for Playgrounds

Pros:

- Wood chips are easy to install; professionals can usually complete the job in about one day.

Cons:

- Installers need to clean the area and make sure the perimeter is outlined with some type of edging to keep the wood chips in place. Some playground surfacing options (such as poured rubber or rubber tiles) don’t require edging – the material naturally stays in place.

- Installation isn’t a once-and-done type of thing. Wood chips needs regular maintenance (including adding more material) in order to maintain their critical fall hall requirement. If you do not maintain the specific installation depth on a playground, children who fall are at risk of serious injury.

Next Steps

Now that you’ve learned more about the basics of wood chip surfacing, you probably want to consider other, safer playground flooring options.

We might be biased, but we strongly recommend considering poured rubber and rubber tile playground surfaces. The reason we only install those options is because we honestly believe they’re some of the best surfacing options for your playground.

You probably still have questions — please feel free to contact us for answers. Again, we don’t offer to install wood chip playground surfacing (because we don’t think it’s good for kids). If you’re ready to take the next steps to choosing the right type of playground surfacing for your situation, reach out to us to request a free quote (for poured rubber or rubber tile playground surfacing). We’d love to help you create a place for adventure!

With so many different qualities and characteristics to consider, choosing a playground surface can be bewildering. That’s why we’ve created an ultimate guide of all the pros and cons of 11 of the most popular playground surfaces, from wood chips to recycled rubber mulch.

FAQ

Yes. Wood chips are one of the cheapest playground covering options, above only pea gravel and sand in terms of cost. They do, however, require regular upkeep, such as raking for hazards and maintaining an even surface level.

Woodchips do not meet ADA requirements for surfaces that allow for wheelchairs and other mobility devices. So if you’re looking to build an accessible playground, wood chips aren’t your best option.

They can be. A 9-inch layer of wood chips will allow a child to safely land from a 10-foot fall, according to American Standard Testing Methods (ASTM), the institution that sets industry safety standards such as this critical fall height requirement.

Not so long ago, playgrounds were fairly dangerous places for children to play. Monkey bars and climbing towers 10 feet tall, everything made of metal that gets hot in the sun not to mention its propensity to rust in the rain, and play surfaces that were made of rock hard dirt or even pavement. Safe playgrounds were not the norm. Children would often get severe burns from the metal play equipment and broken limbs or worse from falling off the tall contraptions onto hard surfaces. According to a study released by the

Not so long ago, playgrounds were fairly dangerous places for children to play. Monkey bars and climbing towers 10 feet tall, everything made of metal that gets hot in the sun not to mention its propensity to rust in the rain, and play surfaces that were made of rock hard dirt or even pavement. Safe playgrounds were not the norm. Children would often get severe burns from the metal play equipment and broken limbs or worse from falling off the tall contraptions onto hard surfaces. According to a study released by the