While researching poured rubber safety flooring, you’ll find that it’s also commonly called wet pour rubber, pour-in-place (PIP) rubber, and poured surfacing. Poured rubber has earned its popularity as a top flooring/surfacing choice for high-traffic, high-activity areas like recreation facilities, pool decks, gyms, garages, resorts, dog parks, water parks, splash parks, daycare centers, equestrian centers, amusement parks, commercial patios, and senior centers.

It’s a formidable task to choose the materials for a flooring surface that will experience millions of footsteps. We often talk to daycare directors, rec center administrators, and city managers who feel overwhelmed by the options and corresponding information to sift through.

Let’s look at its cost, and why poured rubber makes for an economical choice in the long run.

Wet Pour Rubber Cost (Installed)

What’s the price of installing poured-in-place rubber safety flooring per square foot? Depending on safety requirements, color choices, patterns, the condition of the existing surface, location, and a few other factors, the cost of a poured rubber surface for a 1,000+ sq. ft. area generally ranges between $9 to $18 per sq. ft. installed. This is the same cost as a poured rubber playground surface.

Poured-in-place rubber safety surfacing is mixed and hand-troweled on-site (watch videos of the installation process we use).

Poured rubber surfacing is durable, soft, and can’t splinter, which makes it a surfacing option that requires little maintenance. Poured rubber lasts longer than other options, such as wood or mulch, before needing replacement.

Using this type of surface can also make your space eligible for LEED® credits and state grants, helping to defray the up-front cost of installing the rubber safety flooring.

Peace of mind when it comes to safety costs

Poured rubber flooring is ADA-compliant, meaning it’s wheelchair accessible and safe for those with physical disabilities. Pour-in-place rubber is widely viewed as the best accessible/inclusive safety surfacing option.

Poured-in-place rubber is extremely shock-absorbent, more than any other type of recreational flooring option. According to American Standard Testing Methods (ASTM), the institution that sets industry safety standards, it only takes 4.5 inches of poured rubber to allow a child to fall on it safely from a height of 10 feet, which is the “yardstick” height to which different flooring materials are compared.

It’s a popular option to use poured rubber for pool decks and at places like senior centers because it has an extremely non-slip surface.

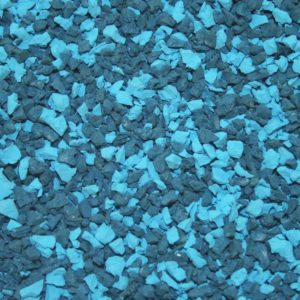

There are different types of poured rubber available, so it’s important to note that adventureTURF only uses premium rubber made from compounds such as EPDM and SBR, plus natural materials (free of wood, wire, and other contaminants).

Low ongoing maintenance expenses

That’s all well and good, but how much time and money is involved in the maintenance of poured rubber safety surfacing? One of the strongest cost-saving factors when considering a poured rubber surface is, unlike other surfacing options, it requires very little maintenance. For example, the annual replacement of wood chips can have a significant impact on an annual budget. A pour-in-place surface will generally last about 10 years (depending on foot traffic) before repair or replacement is required — no need to truck in new surface filler every spring. This means you won’t need to plan to regularly bring in new surface filler, like you would other flooring options, such as loose fill materials.

Maintenance and upkeep is simple. Periodically the surface can be treated with a coating to renew its wear and weather resistance. On especially high-traffic surfaces, simple repairs can be completed to replace damaged areas.

Next Steps

Elsewhere on our website, you may read more about all of the rubber flooring options we offer and find our answers to some FAQs. We’ve also created a gallery where you can browse some of the awesome designs we’ve completed across the country.

You probably still have questions. We’d be happy to help. Contact us. And if you’re ready to take the next steps, reach out to us to request a free quote. We’d love to help you install your poured rubber surfacing project!

GET A FREE QUOTE »

![]() We service the entire USA. Contact us for more information or get a free quote.

We service the entire USA. Contact us for more information or get a free quote.

New playground surfacing isn’t inexpensive (

New playground surfacing isn’t inexpensive (